PROCESS

CONTINUAL IMPROVEMENT

at the service of operational excellence

Our ability to meet market challenges and satisfy customer demands is not a coincidence. It’s the result of our organised and optimised processes, which are deeply embedded in our corporate culture. We continuously strive to refine our workflows, innovate our production techniques, and upgrade our machinery, ensuring operational excellence and competitiveness.

Our commitment to excellence is evident in every aspect of our business. We ensure that our customers receive the highest-quality packaging solutions meticulously designed and manufactured to meet their precise requirements.

AN ORGANIZATION

geared towards industrial efficiency

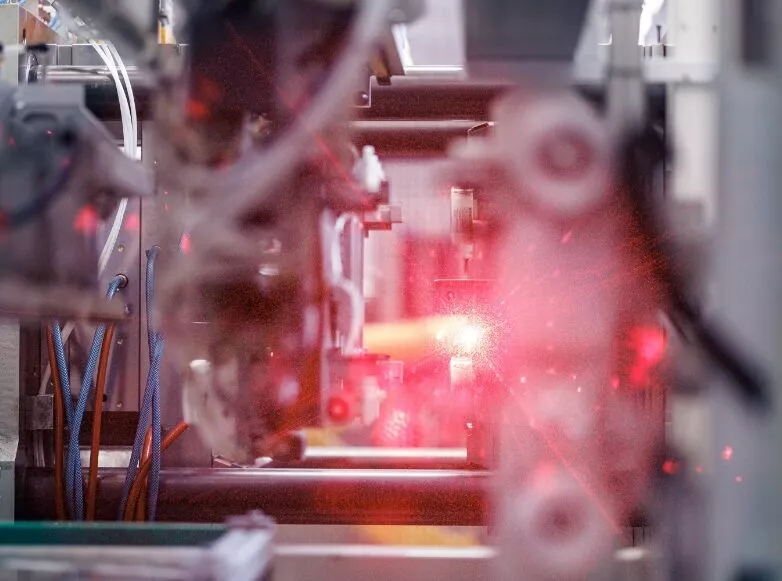

Our quest for productivity is evident in the continuous improvement of our processes. Aware of the challenges posed by market changes and the rise of mass retailing, we have optimised our industrial operations through technical and organisational innovations, as evidenced by the ongoing enhancement of our machinery. This evolution, guided by lean manufacturing principles, ensures optimised production flows, increasing flexibility and operational efficiency.

Our approach starts with an innovative design office, where every product is meticulously engineered to meet customer specifications precisely.

Secondly, our streamlined production methods ensure efficient, high-quality manufacturing, while our optimised shipping logistics ensure that every product reaches our customers in excellent condition and on time.

This cohesive structure strengthens our ability to deliver precise, well-thought-out solutions while maintaining exceptional customer satisfaction at every stage of the process.

OUR STRENGTH:

the responsiveness of all

Our adherence to lean manufacturing principles is reinforced by optimal order management and precise production planning.

Our production facilities, designed for large-scale production runs, have been adapted to meet an ever-increasing diversity of products.

Our proven organizational structure ensures maximum efficiency and enables us to respond swiftly and effectively to changing market demands. Through these processes, we guarantee an agile response tailored to our customers’ needs while maintaining top-tier industrial performance.

ANTICIPATE AND INNOVATE:

the competititve advantages of a trailblazer

From the outset, we have embraced a lean approach to our advanced production processes. As early as the 90s, we were among the pioneers in introducing stack moulds. Building on this innovation, we developed family moulds, both technologies aimed at enhancing the productivity of our manufacturing facilities.

Continuous improvement of our machinery includes automation, a central element of our strategy to consistently boost efficiency and resilience.

Our investment in cutting-edge technology and innovative methods underscores our commitment to meeting our customers’ critical cost, quality, and delivery considerations.

WE FOCUS ON THE NEEDS

of our customers

The sophistication of our products goes beyond design; it is intrinsically linked to their functionality and ability to deliver a unique consumer experience.

By combining advanced injection techniques with innovative design, we create products that meet functional requirements and evoke an aesthetic and sensory resonance.

This holistic approach results from close collaboration with our partners, ensuring each project is tailored to their specific needs.

TECHNOLOGY

at the service of sophistication

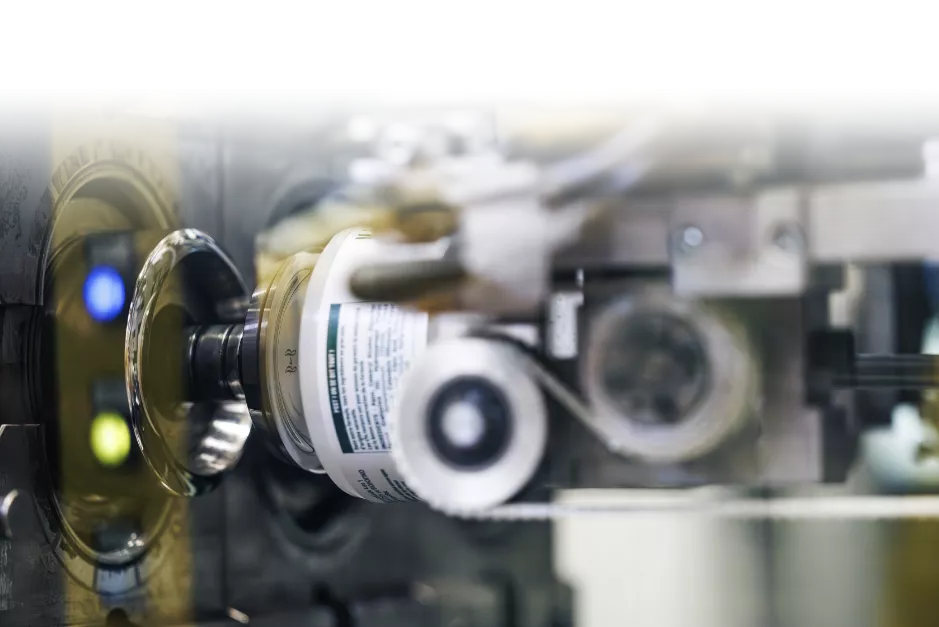

We employ innovative processes to produce highly sophisticated parts.

A prime example is IML, with Orgelet (Franche-Comté, France) being its birthplace. This technology ensures a perfect finish and superior print quality.

Furthermore, we possess expertise in bi-material and co-injection techniques, which enable us to combine several materials to meet our customers’ needs.

These methods enhance products’ functionality and aesthetic appeal, offering a wide range of textures, colours, and mechanical properties while providing single-material and recyclable solutions.

These advanced technologies meet and exceed our customers’ expectations by delivering innovative, tailor-made solutions that elevate their market offerings and enable them to stand out from the competition.